At the beginning there is always the idea

On the basis of the sketches paper pattern are made

Matching leather must be established

Additional items as lining, inlay material and metal parts ( zippers, buttons) need to be choosen

Punching tools are developed to cut the leather for production

The leather is cut with usage of the punching machine

A wallet persists of up to 50 single parts

all pieces are prepared for further production steps

Some parts need to be glued and folded in

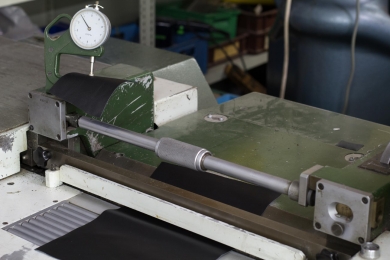

Some leather parts need to thinned with the splitting machine

Some parts need to be splitted at edges , for better folding in

Each wallet is handcraft

After gluing parts together, they are sewed as well